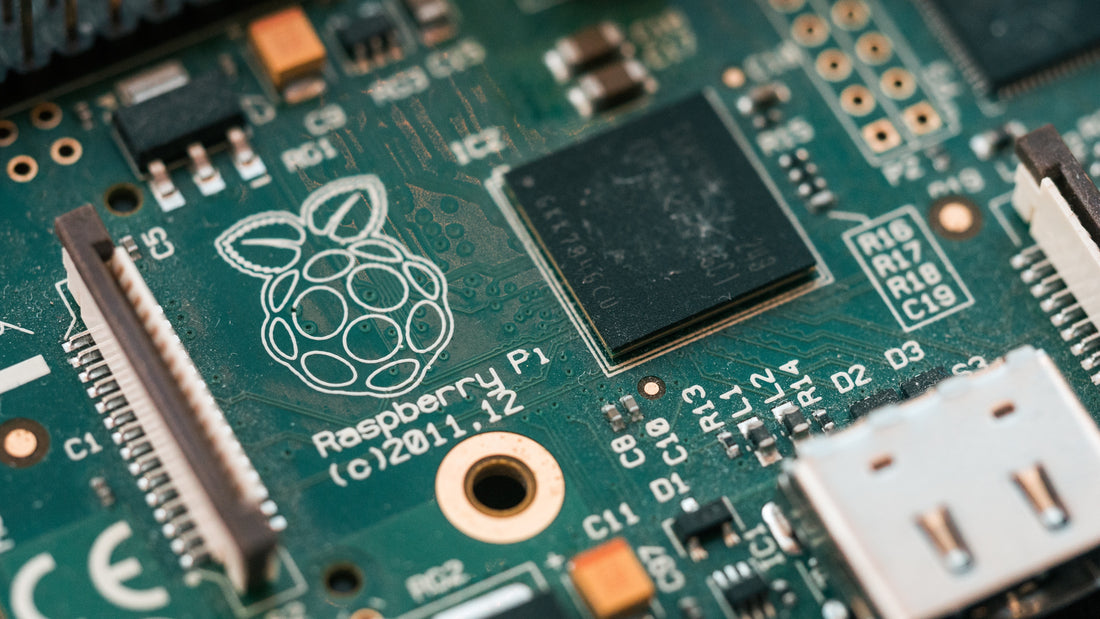

Raspberry Pi, the versatile and compact single-board computer, has become a favorite among DIY enthusiasts and developers for its ability to interface with various sensors. Whether you're working on a home automation project, building a weather station, or experimenting with IoT applications, connecting sensors to your Raspberry Pi is a crucial step. In this article, we'll explore the available GPIO capabilities of Raspberry Pi as well as different methods of connecting sensors to these pins directly, including soldering, direct connection, and using a protoboard or through popular HAT extensions.

What is Raspberry Pi GPIO?

GPIO (General Purpose Input/Output) pins serve as an interface between the outside world and the Raspberry Pi. They are flexible in such a way that they can be dynamically configured to function either as inputs or outputs. As inputs, they can receive signals from various external devices such as sensors, buttons, or switches. As outputs, they can send signals to control LEDs, motors, or other actuators. This bidirectional capability makes the GPIO pins a central element in creating interactive and responsive projects.

Physical Exploration of GPIO Pins

Physically, the GPIO pins are located along the edge of the Raspberry Pi board, typically grouped in sets of 40 pins. This is also called GPIO header and is presented in the image below provided by Raspberry Pi Foundation. Each pin is labeled with a specific GPIO number, and some pins serve special functions such as power, ground, and communication interfaces like I2C and SPI. The GPIO pins are not only a means of connectivity but also a canvas for innovation, allowing users to craft diverse projects that range from simple LED blinkers to complex IoT applications.

Power Pins

The power pins on the Raspberry Pi play a crucial role in providing electrical power to the board and its connected peripherals. Understanding these power pins is essential for properly powering and configuring your Raspberry Pi. We will not cover each Raspberry Pi model here, but we will talk about pins that can be found in majority of latest models:

5V (Pin 2):

The 5V pin is used to supply a regulated 5-volt power to the Raspberry Pi. This voltage is crucial for the board's operation and for powering connected devices that require 5V.

3.3V (Pin 1):

The 3.3V pin provides a regulated 3.3-volt power supply. Many sensors and components, especially those interfaced with the GPIO pins, operate at 3.3V.

Ground (GND, Pins 6, 9, 14, 20, 25, 30, 34, and 39):

There are multiple ground pins scattered across the GPIO header. These pins are used as the reference ground for the power supply and for completing electrical circuits.

5V Power for USB (Pins 4 and 17):

These pins are often used to provide power to USB peripherals connected to the Raspberry Pi. The 5V from these pins is directly connected to the 5V power rail.

Power Over Ethernet (PoE) Pins (Pins 1, 2, 3, and 6):

On certain Raspberry Pi models, there are PoE pins for Power over Ethernet. This feature allows the Raspberry Pi to receive both data and power over a single Ethernet cable, simplifying cable management.

It's important to note a few key considerations regarding power on the Raspberry Pi:

Voltage and Current Requirements

The Raspberry Pi models have specific voltage and current requirements. Ensure that the power supply you use meets these specifications to prevent instability or damage to the board.

Powering Peripherals:

USB peripherals, sensors, and other connected devices draw power from the Raspberry Pi. Be mindful of the total power requirements, and use an external powered USB hub if needed.

Ground Connection:

Proper grounding is essential to ensure a stable electrical reference. Connect the ground of the external power supply to one of the ground pins on the Raspberry Pi.

Polarity:

Pay attention to the polarity of the power supply. Connecting the power pins incorrectly can damage the Raspberry Pi.

Before powering up your Raspberry Pi, always double-check the documentation specific to your model and the most recent information, as newer models may have variations in their power requirements and pin configurations.

Connecting to the Raspberry Pi GPIO Directly

1. Soldering: Precision and Permanence

Soldering is a common method used for establishing a secure and permanent connection between a sensor and a Raspberry Pi. This method involves melting a metal alloy (solder) to create a bond between the sensor's pins and the Raspberry Pi's GPIO (General Purpose Input/Output) pins. Soldering provides a stable and reliable connection, making it ideal for projects where the sensor setup is not likely to change frequently.

Steps for Soldering:

- Gather the necessary equipment: soldering iron, solder wire, flux, and a helping hand tool.

- Identify the GPIO pins on the Raspberry Pi and the corresponding pins on the sensor.

- Apply a small amount of flux to the pins to improve soldering efficiency.

- Use the soldering iron to melt a small amount of solder onto the pins, creating a secure connection.

2. Direct Connection: Quick and Temporary

For projects that require a more flexible setup or if you're testing multiple sensors, a direct connection might be the way to go. This method involves attaching jumper wires directly from the sensor to the Raspberry Pi's GPIO pins without the need for soldering. While this approach lacks the permanence of soldering, it provides a quick and easy way to prototype and experiment with different sensor configurations.

Steps for Direct Connection:

- Identify the GPIO pins on the Raspberry Pi and the corresponding pins on the sensor.

- Connect jumper wires from the sensor to the appropriate GPIO pins on the Raspberry Pi.

- Ensure a secure connection by using male-to-female jumper wires or additional connectors.

- This method allows for easy removal and replacement of sensors without the need for desoldering.

3. Protoboard: Flexibility and Reliability

A protoboard (prototyping board) offers a middle ground between soldering and direct connection. It provides a platform for attaching sensors and other electronic components using jumper wires without the need for soldering. Protoboards are reusable and offer flexibility, making them ideal for projects that involve frequent changes to the sensor setup.

Steps for Using a Protoboard:

- Place the sensor on the protoboard and secure it using the provided holes or adhesive.

- Connect jumper wires from the sensor to the protoboard and from the protoboard to the Raspberry Pi's GPIO pins.

- Utilize the protoboard's layout to organize and manage multiple sensor connections.

- Enjoy the ease of reconfiguring your setup by rearranging components on the protoboard.

Connecting sensors to a Raspberry Pi opens up a world of possibilities for creative projects and experiments. Whether you choose the precision and permanence of soldering, the quick and temporary nature of direct connection, or the flexibility of a protoboard, each method has its advantages. Consider the specific requirements of your project, and don't hesitate to experiment with different connection methods to find the most suitable approach for your unique application. Before concluding, let us explore another possibility when it comes to connecting sensors to Raspberry Pi - popular HATs.

Connecting to the Raspberry Pi GPIO Through HATs

In the domain of Raspberry Pi, Hardware Attached on Top (HAT) modules represent a noteworthy advancement, simplifying the integration of sensors and additional functionalities. Essentially, a HAT is a standardized add-on board designed by the Raspberry Pi Foundation to seamlessly connect to the GPIO pins of a Raspberry Pi. This standardized form factor streamlines the physical attachment process, ensuring compatibility across different HATs and creating a user-friendly environment for users of varying expertise levels.

One of the primary advantages of utilizing HATs lies in their ease of connection. With labeled headers and a standardized form factor, HATs simplify the physical attachment process, reducing the risk of incorrect connections. This standardized approach ensures compatibility across different HATs, fostering a user-friendly environment for both beginners and experienced Raspberry Pi enthusiasts.

Beyond the straightforward physical connection, HATs often bring additional features to the table. They can encapsulate not only the sensor itself but also include components such as voltage regulation, LEDs, buttons, or other functionalities that enhance the overall capabilities of the connected sensor. This integrated approach not only reduces the complexity of wiring but also adds value through supplementary features.

Moreover, HATs often come with pre-configured software or scripts, streamlining the software integration process. The Raspberry Pi community frequently provides support and official libraries for many HATs, enhancing the user experience and making it more accessible for a broader audience. This level of integration makes HATs an attractive option for those seeking a plug-and-play solution without delving deep into the intricacies of software configuration.

However, despite their numerous advantages, HATs may not be the ideal solution for every scenario. When opting for individual sensors without HATs, users gain a heightened level of flexibility and customization. This approach allows for the precise selection of sensors based on specific project requirements and the utilization of various connection methods, such as GPIO, I2C, SPI, or USB, depending on the sensor's nature.

In conclusion, the choice between utilizing HATs or not hinges on the individual's project requirements, preferences, and the nature of the sensors to be integrated. While HATs offer a convenient and organized solution, providing a seamless connection and additional features, the flexibility and customization of connecting sensors directly may appeal to those seeking a more hands-on and cost-effective approach to Raspberry Pi projects.